Designing SmartSort: Roadie’s Warehousing App

Summary

Results

Roadie Overview

Challenge

Retailers rely on inefficient delivery solutions and struggle with overhead costs and delays. How can Roadie get their products to their customers faster than ever?

Opportunity

Roadie can leverage retailer warehouses and turn them into sorting and distribution centers.

Solution

Working with Fanatics, I designed an MVP product that enables sorting of packages and pickups directly from warehouses.

Discovery

Definition

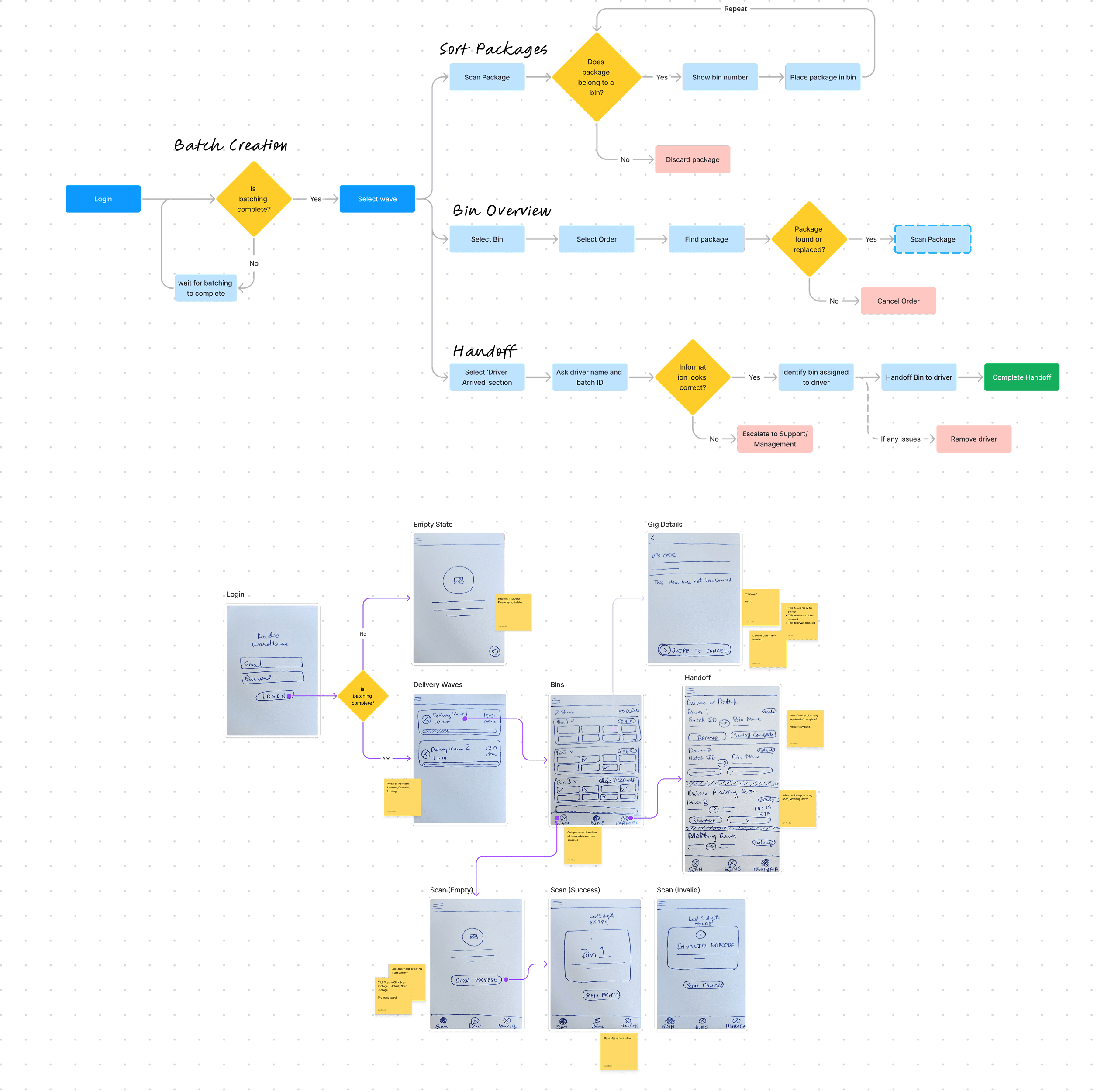

Key Requirements

-

Scan and sort packages into bins -

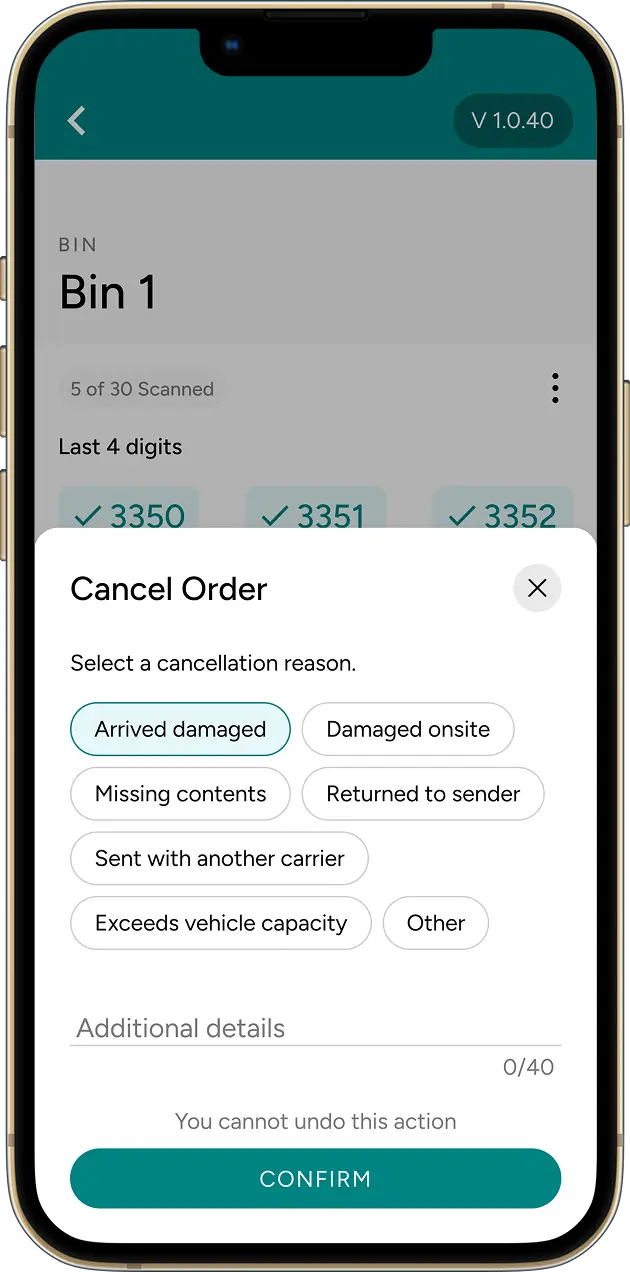

Handle exceptions (missing, damaged and ineligible packages) -

Monitor scan progress -

Verify scan completion -

View driver assignment

Designing for Warehouse Reality

-

Easy to learn in minutes -

Does not slow down users

User Flow & Initial Sketches

Designing under operational constraints

-

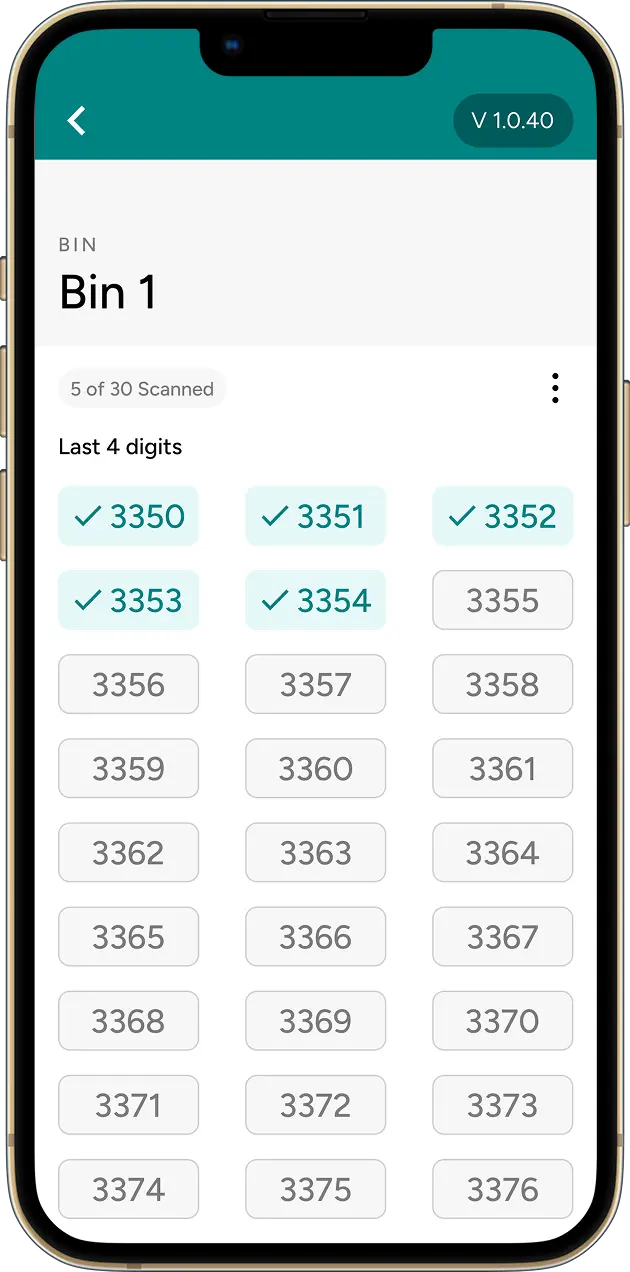

Adding secondary bin scan

The Fanatics team needed confirmation that employees placed packages in the right bin. Given how quickly users move when sorting, such errors are bound to happen. To prevent missorts, I added a step where user needs to scan the bin after scanning the package. -

Dropping the wave concept

To allow warehouses to operate in waves (e.g. AM wave, PM wave), I designed an overview to select waves. This would keep information organized when waves overlap. However, in reality the warehouses did not operate in waves with shipments from waves rolled over into existing wave. -

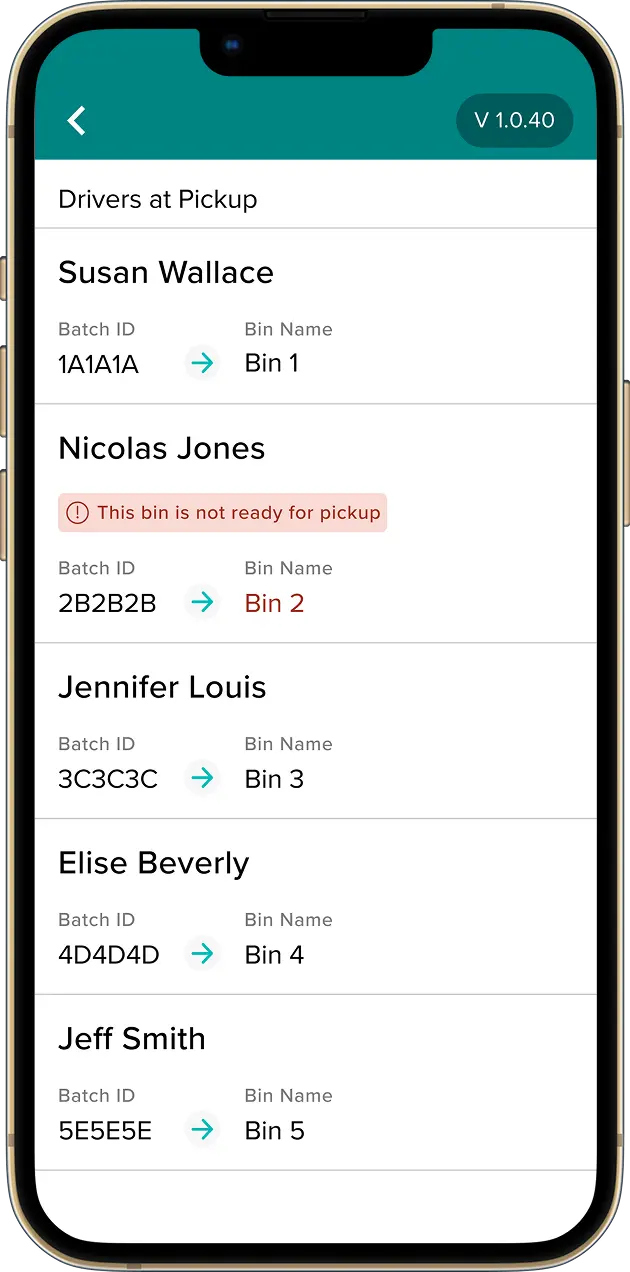

Supporting driver verification

To prevent drivers from claiming bins and enforcing verification, I suggested that we use the driver Batch ID. Instead of revealing the bin number on the driver app, the warehouse user verifies the Batch ID provided by the driver and maps it to the corresponding bin number.

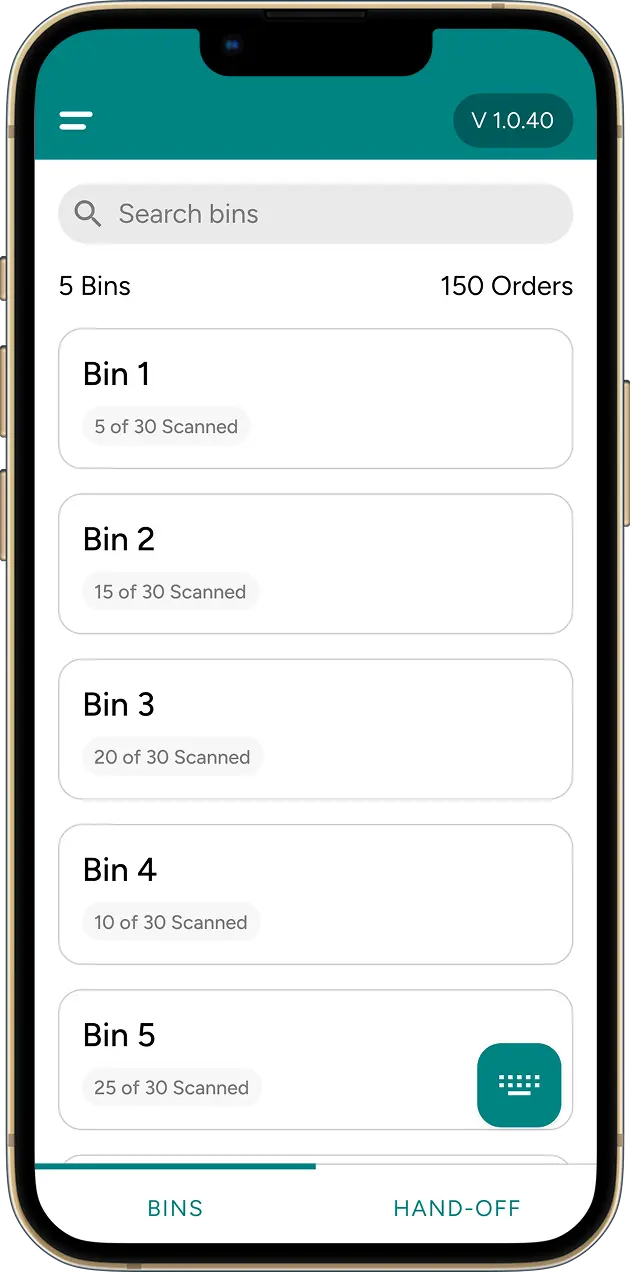

Final Designs

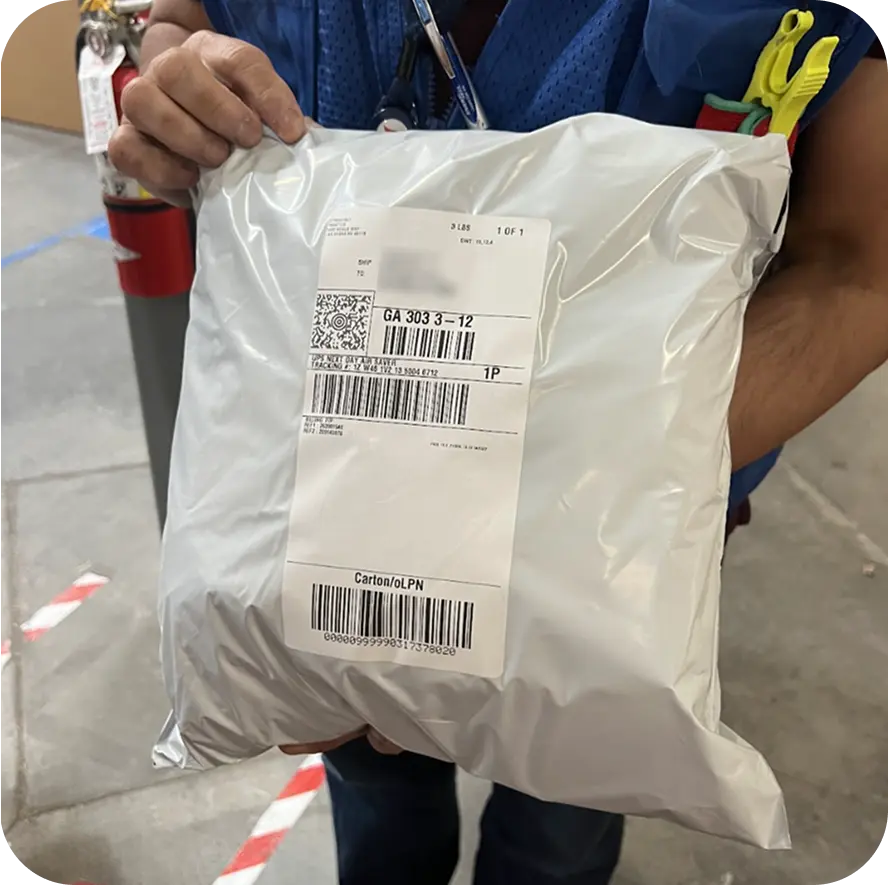

Packages arrive at the warehouse

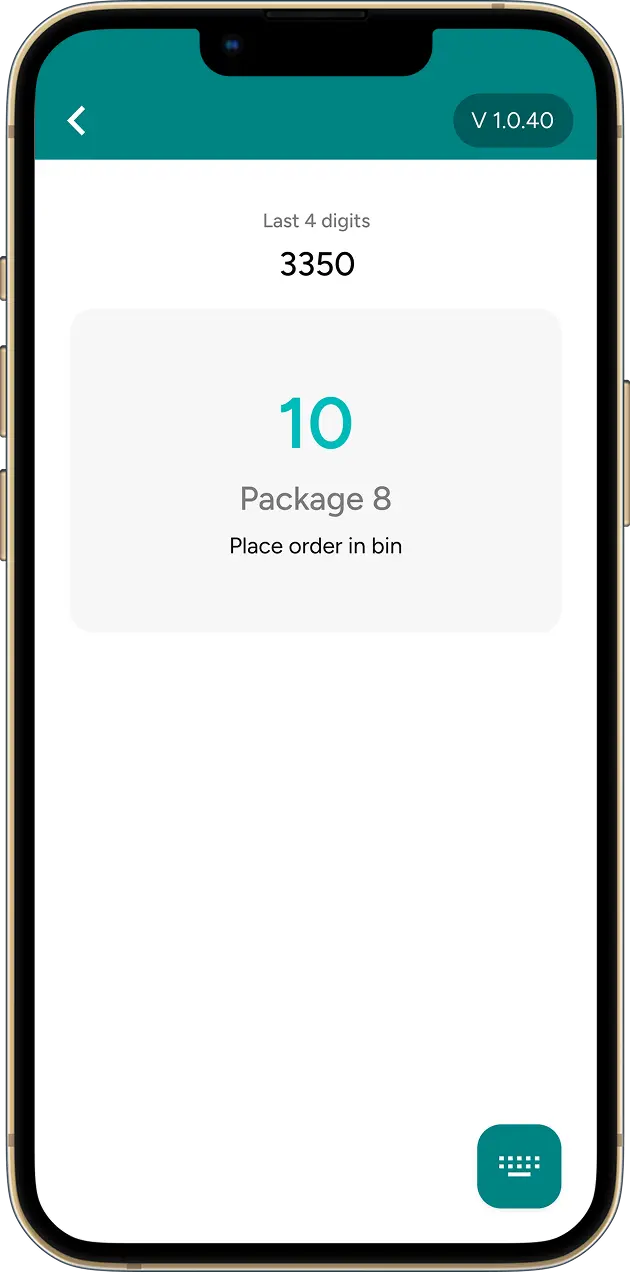

Sort packages into bins

Verify all packages in a bin

Cancel missing or damaged packages

Handoff bins to drivers for pickup

Business Outcomes

-

Fanatics expanded SmartSort operations to 8 warehouses within 6 months -

Contributed to a 19% reduction in overhead costs and 25% volume growth as warehouse-based fulfillment scaled -

Enabled a reduction in delivery time from 2–3 days to under 24 hours

Starting Roadie’s Own Warehouses

SmartSort now supports the sorting and handoff of hundreds of thousands of daily shipments, contributing to over 25M+ total shipments processed through Roadie-operated warehouses.